If you’re in the market for a nutrition powder machine, there are a few different types you can choose from.

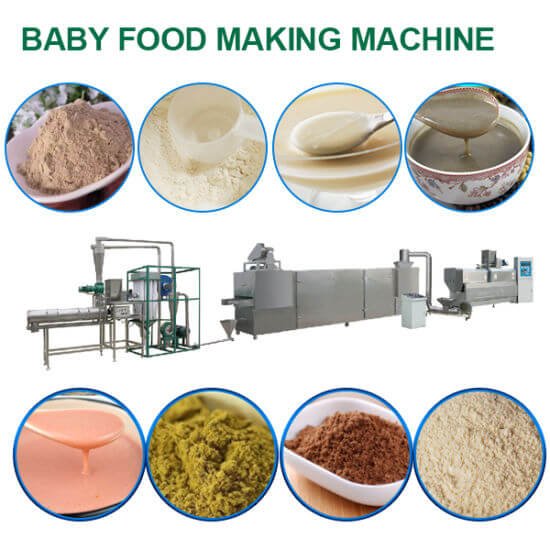

There are many advantages to choosing a baby powder food production line, including advanced technology and efficiency.

Nutritionally complete food is very important for baby’s development, and a balanced diet can be easily consumed for a long time without compromising its nutritional value.

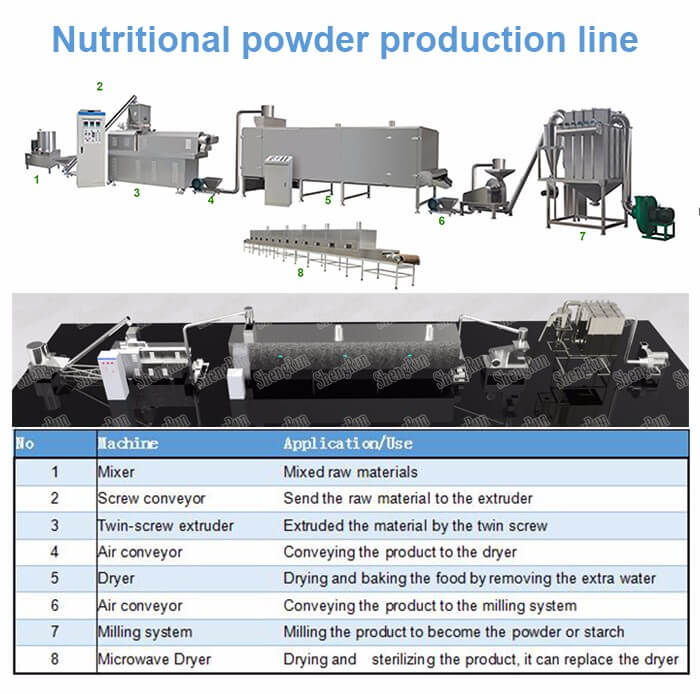

The extruder of a nutritional powder machine manufacturer uses a frequency conversion speed regulation and alloy steel specially treated to withstand high pressure.

The twin-screw design ensures longer transmission tasks.

EM small-batch drum mixer

The EM small-batch drum mixer is a highly versatile, multi-processing unit designed to handle both small-batch and master batch mixing jobs.

Its design is versatile enough to serve as the foundation for a number of specialized industries.

Unlike conventional mixers, the EM can handle multiple processes simultaneously, such as coating, homogenization, and liquid dispersion.

Using the tumbling motion, it ensures the movement of droplets and particles in the mass.

The powder is mixed evenly through the machine’s three-dimensional motion.

Its rotary and shaking motions achieve homogeneity more quickly and efficiently.

In addition, EM small-batch drum mixer nutrition powder machine manufacturer

ComDisc(r) technology

The ComDisc(r) technology for nutrition powder machines allows contract manufacturers to fine-tune the production process for a wide variety of nutritional supplements.

The proprietary helical ribbon blades actively deagglomerate protein powder to ensure a uniform and homogenous powder blend.

This machine also allows for variable filling levels, so contract manufacturers can fine-tune their production processes.

ComDisc(r) technology is the latest advancement in amixon(r) batch mixing equipment, which offers a full range of processing functions and variable filling levels.

Matcon

The advantages of the Matcon Nutrition Powder Machine Manufacturer’s production system are obvious.

The system minimizes waste, downtime, and manual handling steps while maximizing product integrity and profitability.

With the cone valve, the production system enables continuous production while cleaning one container.

This feature ensures consistent product quality and consistency, and allows future product formulations to be easily incorporated into the manufacturing process.

The versatility of the Matcon Nutrition Powder Machine Manufacturer’s system allows it to handle a wide variety of ingredients.

The patented IBC System from Matcon is a blending and transfer vessel in one.

With this unique system, it is easy to change recipes and blends without having to shut down the entire production line.

The unique cone valve also protects against segregation and provides assured discharge.

The patented design makes cleanup a breeze. Matcon Nutrition Powder Machine Manufacturer’s technology is backed by a five-year warranty.

Stoke #328 tablet press

Designed to produce multiple sized tablets, the Stoke #328 Tablet Press is a workhorse for the production of a variety of tablet products.

With its 45 punch stations, the machine can manufacture a variety of tablet sizes and powdered formulas.

The machine is compatible with the Bosch GKF 400 Encapsulator, which produces “0” and “00” size capsules and can produce over 400 per hour.

Designed with small batch production in mind, the NP-RD30 features an innovative wash-in-place design and high containment capabilities.

The machine is portable and self-contained, and is perfect for product development, scale-up, and clinical batch production.

This machine is fully compliant with applicable FDA regulations. It is also available with a semi-automatic control system for optimum process flexibility.

Bosch GKF 400 Encapsulator

The Bosch GKF 400 Encapsulator is a highly accurate capsule filler.

With a speed of 400 capsules per minute, it is an excellent choice for research and development applications.

The machine features high-precision functional processes to maximize accuracy.

Capsules fed pre-locked are aligned and oriented, while capsules with two caps are rejected.

The machine’s three-up tamping procedure helps reduce the occurrence of dust. The results are consistent capsule filling with zero product loss.

The Bosch GKF 400 Encapsulator is capable of processing 150,000 capsules per hour and 140 cycles per minute.

It has an 18 mm bore and is equipped with an automatic troubleshooting system.

It also features in-process weight checking and an integrated weight-checking system.

Its robust design, innovative features, and advanced software ensure its maximum uptime.

And with a minimum purchase price of $28,499, this machine is an excellent choice for many applications.

Rice grain blending machine

In order to produce a quality nutritional powder, you need to blend rice with a liquid.

Typically, this liquid is water, bone broth, or veggie broth. Fresh breast milk or formula are also acceptable.

These types of liquids are added in small increments.

Once the rice is blended, you can add other ingredients to make your nutrition powder.

If you are looking for a more affordable option, you can opt for a rice grain blending machine.

There are two types of rice milling systems: one-step milling and two-stage milling. Single-pass milling removes the husk and bran layer from the rice in a single pass.

The one-step milling method is discouraged by the International Rice Research Institute, but it is widely used for custom milling.

Two-step milling removes the husk and bran layers one at a time, and is more common in rice-growing countries.